Tights or pantyhose are a type of legwear that are made by knitting fabric in a cylindrical shape creating a long tube.

At We Love Colors we have offered tights in over 50+ different colors since 2002.

We partner with the best factories around the world to create products that are durable and inclusive.

We broke down the process of making tights in a few simple steps, just to give you a big picture.

- Yarn Selection

- The first step is to select the type of yarn to be used. Yarns can be made from different fibers, including cotton, wool, silk, nylon, polyester, and others. The type of yarn used will depend on the desired properties of the tights, such as stretch, durability, and warmth.

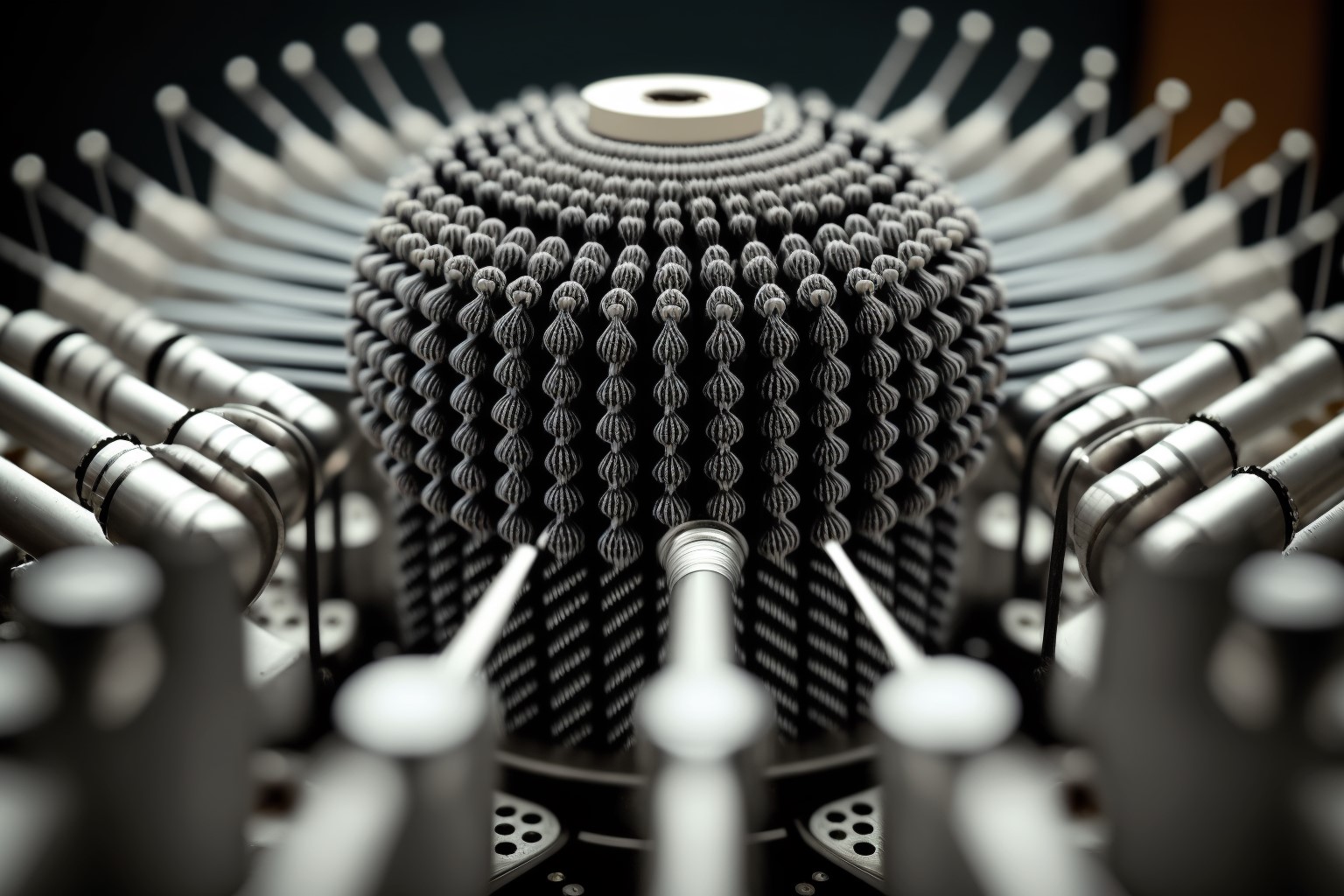

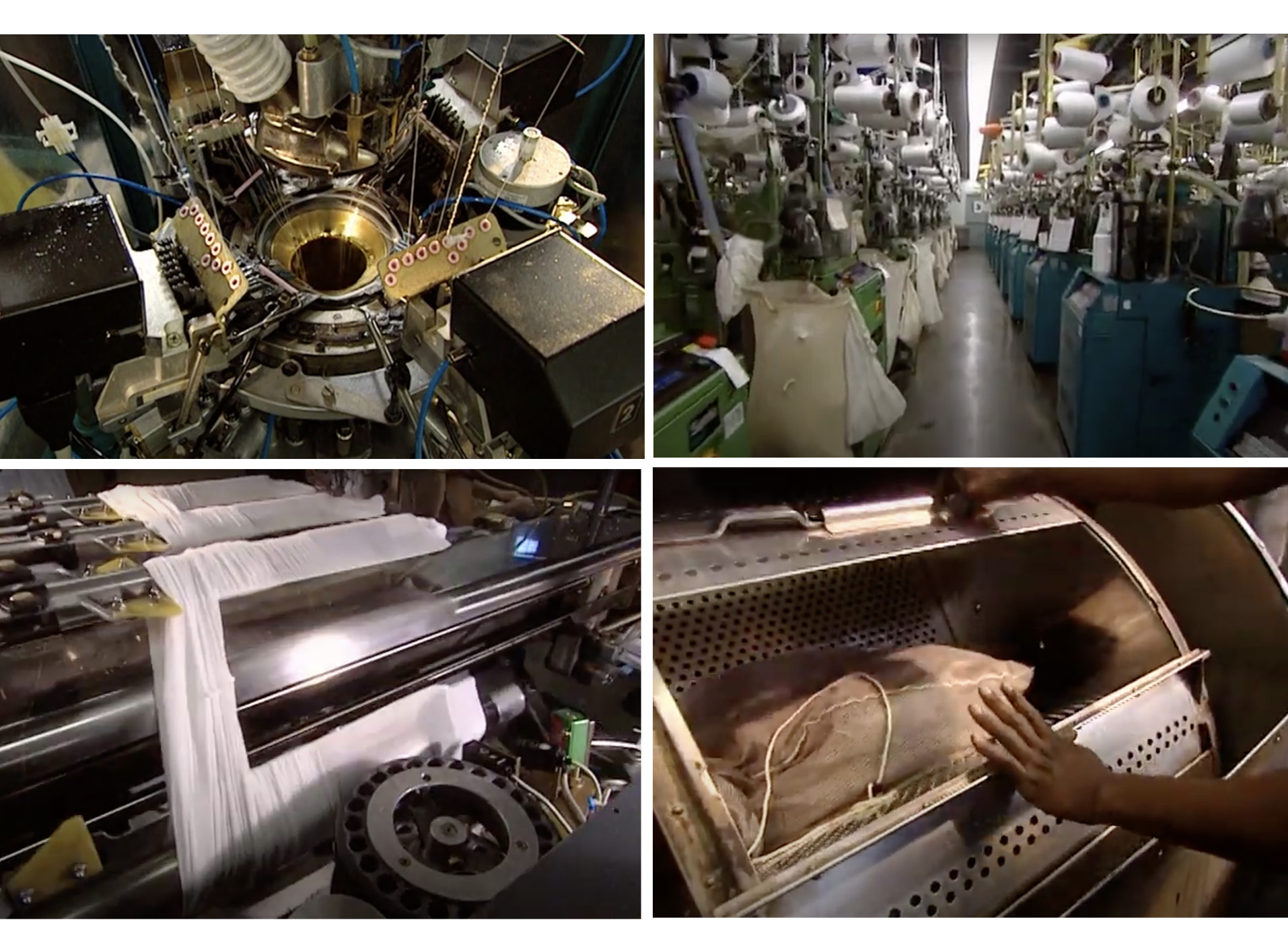

- The selected yarn is then fed into a knitting machine. The knitting machine has a series of needles that knit the yarn into a tube-like shape. The number of needles used in the machine will determine the thickness of the tights. The knitting process also allows for the creation of different patterns and designs in the fabric. The tights that we offer are made with over 140 needles. Yep! Over a hundred. It’s crazy, no?

- After the knitting process, the fabric is usually dyed to the desired color or pattern. This can be done using different techniques, including dipping, spraying, or printing. At We Love Colors we do this step last!

- Once the fabric has been dyed and dried, it is cut into individual panels using a cutting machine. The number of panels used will depend on the desired style and size of the tights. This is the seam that you find the middle, on plus size tights you could find two seams.

- The individual panels are then sewn together using a sewing machine. The sewing process involves joining the front and back panels together or sewing the legs together if panels are not needed. Lastly, any necessary reinforcements, tags or elastic bands are added. The seams can be regular or flat.

- The final step in the process involves trimming any loose threads and ensuring that the tights are free of any defects.

- The tights are then packaged and shipped for sale. We do this by hand here in Miami, we avoid using plastic and cardboard, we simply recycle imperfect tights to create elastic bands that we wrap around each one of our products. Big companies use machines to do the boarding process (term used for steaming), folding and packaging.

Knitting

Dyeing

Cutting

Sewing

Finishing and Quality Control

Ready to go!

We hope that now you have a better idea of the process behind each pair of tights you wear.